SIMOTICS XP low-voltage explosion-proof motor

Category:Motor

+86-152-9510-6006 Online consultation 詩恩斯電氣

詩恩斯電氣

Performance is compelling, trust is everything

With Siemens SIMOTICS XP explosion-proof motors, you will be safer than ever before. This is because Siemens' rugged explosion-proof motors can operate for long periods of time, and even under extreme conditions, they will not fail, whether in linear or variable frequency operation. These motors have had hundreds of thousands of practical experiences around the world. This is not all the advantages: Siemens explosion-proof motor series is seamless, with greater safety and higher operating efficiency to meet more needs! We can also provide dual protection drive solutions to meet special requirements. In this way, this series of motors is excellent both in terms of application range and in meeting global market requirements.

Advantages at a glance

SIMOTICS XP Low Voltage Explosion-proof Motor Highlights

Preparing applications for future efficiency requirements

For example, all available motors require IE3 energy efficiency, IE4 ≥ 250 kW, Ex Ec, Ex tb/tc, and available IES values

All the advantages of a common platform SIMOTICS low-voltage motor (including tools)

For example, the same look and feel, all products in the same tool, and the expert community sharing expertise

Variable frequency operation of any frequency converter

For example, it is used in combination with SINAMICS G/S series and third-party PWM converters; Optional Ex db model at 690 V

Comply with end-user specifications and checklists

For example, the starting current limit of 600% is applicable to most end users, covering all common types of explosion-proof categories

Provide excellent solutions for your industry

Typical Use and Application Fields

Oil and Gas

The oil and gas industry is characterized by high requirements for the drive technology used. This requirement applies not only to the high explosion risk inherent in these two types of commodities, but also to deployment locations, whether they are offshore, polar, or desert areas. The SIMOTICS XP CHEMSTAR model specifically designed for the oil and gas industry considers this aspect. The combination of basic and additional functions ensures greater safety and plant availability for electrical equipment even under extreme conditions of oil and gas production and transportation, while reducing life cycle costs.

chemical industry

In the chemical industry, flammable gases, liquids, and solids are typically converted and processed in various complex processes. Many different factory components present an explosion risk, such as due to flammable solvents, or due to special work processes that can produce related hybrid mixtures. These substances contain potentially explosive gases and dust and have a low minimum ignition energy. Therefore, the motor used must operate continuously and effectively, even in chemically aggressive environments. In the SIMOTICS XP CHEMSTAR model specifically designed for the chemical industry, the electrical equipment is precisely customized for these environmental conditions, ensuring greater reliability and safety.

SIMOTICS XP CHEMSTAR

Reliable, safe, and robust operation

SIMOTICS XP CHEMSTAR

Suitable for high seas - SIMOTICS XP explosion-proof motor certified by classification society

The high seas are also dangerous workplaces. These include offshore drilling and production platforms, as well as oil tankers, explosive chemicals, or liquid natural gas (LNG) vessels, where special care is required. The list of hazardous locations where electric motors are used above and below the deck of such ships or platforms is long.

Below the deck are main propulsion units, bow thrusters, azimuth transmissions, and compressors, as well as pumps and fans for various tasks. Hazardous locations above the deck include winches, cranes, boosters, and deep well pumps. In all these locations, SIMOTICS XP motors with explosion-proof enclosures ensure greater safety - leading international classification society certifications attest to their suitability for marine applications:

LR Lloyd's Register of Shipping (UK)

DNV GL - Det Norske Veritas/GL (Norway/Germany)

BV - French Bureau of Shipping (France)

RINA - Italian Bureau of Shipping (Italy)

ABS - American Bureau of Shipping (USA)

KR - Korea Classification Society

Food - Reliable protection, even if there is dust around

In some areas of the food industry, fine dust can appear in silos, mills, and conveying systems, which can lead to an explosion hazard. For example, it is generally believed that dust explosion hazards are particularly prone to occur in grain processing and bread production. Siemens' SIMOTICS XP motors with dust explosion protection (Ex tb and Ex tc) are specifically tailored to meet these hazardous situations. The dustproof enclosure of this type of motor (protection class IP65, zone 21) can prevent serious accumulation of internal dust. The casing surface temperature of this type of motor will be limited to a level that cannot ignite the surrounding dusty atmosphere. The ventilation system of SIMOTICS XP also ensures that sparks are not generated. Dedicated conductive paint finish can effectively prevent any

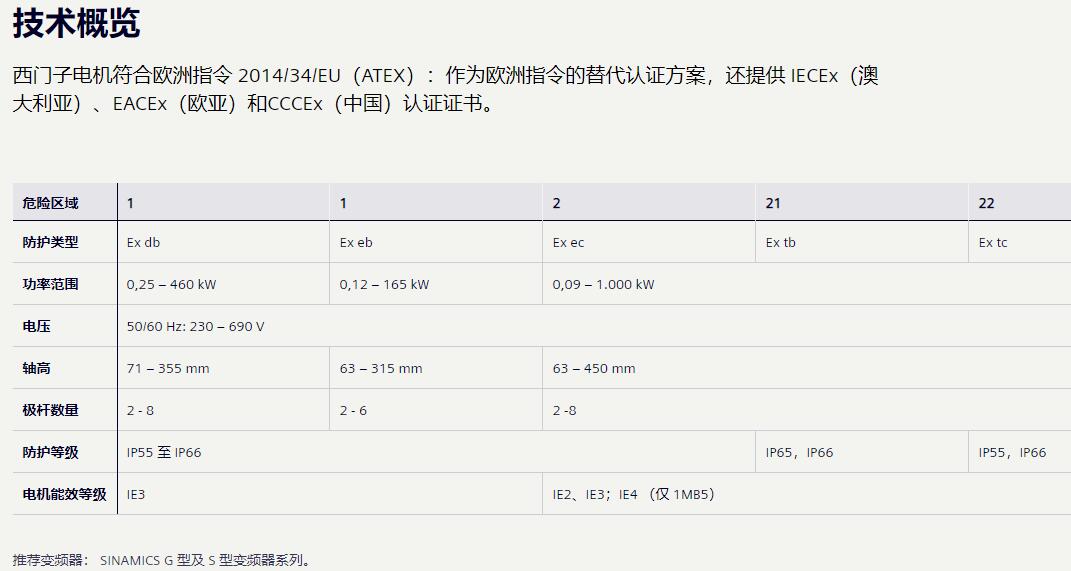

Complete overview of technical data